Maverickson

Well-Known Member

Recently I acquired a fine 7823 ( AER ) G-1 made by California Sportswear. Besides being in nearly perfect condition early on at one time or another unfortunately it must have come in contact with baking soda. Now, I have had some very successful experiences with using baking soda to remove bad odors from leather jackets but costly. Contrary to popular opinion within the forum it should be known that using baking soda on mid to late 1950s G-1 jackets with Conmar aluminum toothed zippers should never be attempted. This jacket is proof of that statement.

These aluminum toothed Conmar zipper assemblies are very hard to find unless attached to 7823 (AER) model G-1. To keep such a unique jacket as original as possible a fine but quite unremarkable like donor jacket was purchased to harvest the same Conmar zipper assembly.

The picture seen below is of the donor jacket having been relieved of it's Conmar zipper assembly. It is interesting to note that the zipper assemblies are originally held in place by two separate stitches. The first stitch and the closest to the outside edge is invisible as it is folding into the zipper flap. When first attaching the zipper it is initially aligned and temporarily pinned or stapled then simply machine stitched in place. In doing so the zipper's initial alignment can be checked and or adjusted as necessary. The final or hand topstitch stitching will be the done using the double needle technique.

In figuring the final reveal of the teeth I found that it would be best to allow an additional 1/16" of an inch reveal. This extra reveal accommodates for the loss or take up from the final step of the visible double needle topstitching.

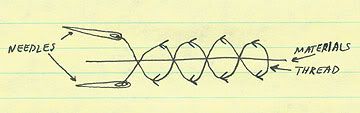

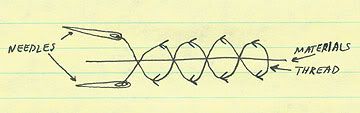

To ensure that the stitching looked as original as possible I utilized the double needle technique to mimic the original machine stitching. Again, this technique was suggested to me by Mark. There are special leather needles available to facilitate this same work and the thread should be waxed. Although slow and methodical as far as I can tell this method of stitching is the best way to guarantee that all the original and existing holes are hit. Not to mention, in attaching the zipper in using this stitch technique there were untold hours of labor to correctly complete this job.

In this picture seen below the jackets right side is in place. The left and final side is being stitched.

As seen above a large paper clip was utilized and kept just forward of the work to facilitate a good finished alignment of the zipper. The needles are both inplace and ready to be pulled. It is important to note that setting and pulling the needles simultaneously helps limit thread tangle.

Although I was able to fill all the existing and original empty stitching the effect of the double stitching tends to round out the original indentation or pocket left by the machine stitch. However, the end result still looks better to me than a second hand machine stitch job.

Some of you might ask, was it worth the trouble :lol: ?

Cheers, Dave

These aluminum toothed Conmar zipper assemblies are very hard to find unless attached to 7823 (AER) model G-1. To keep such a unique jacket as original as possible a fine but quite unremarkable like donor jacket was purchased to harvest the same Conmar zipper assembly.

The picture seen below is of the donor jacket having been relieved of it's Conmar zipper assembly. It is interesting to note that the zipper assemblies are originally held in place by two separate stitches. The first stitch and the closest to the outside edge is invisible as it is folding into the zipper flap. When first attaching the zipper it is initially aligned and temporarily pinned or stapled then simply machine stitched in place. In doing so the zipper's initial alignment can be checked and or adjusted as necessary. The final or hand topstitch stitching will be the done using the double needle technique.

In figuring the final reveal of the teeth I found that it would be best to allow an additional 1/16" of an inch reveal. This extra reveal accommodates for the loss or take up from the final step of the visible double needle topstitching.

To ensure that the stitching looked as original as possible I utilized the double needle technique to mimic the original machine stitching. Again, this technique was suggested to me by Mark. There are special leather needles available to facilitate this same work and the thread should be waxed. Although slow and methodical as far as I can tell this method of stitching is the best way to guarantee that all the original and existing holes are hit. Not to mention, in attaching the zipper in using this stitch technique there were untold hours of labor to correctly complete this job.

In this picture seen below the jackets right side is in place. The left and final side is being stitched.

As seen above a large paper clip was utilized and kept just forward of the work to facilitate a good finished alignment of the zipper. The needles are both inplace and ready to be pulled. It is important to note that setting and pulling the needles simultaneously helps limit thread tangle.

Although I was able to fill all the existing and original empty stitching the effect of the double stitching tends to round out the original indentation or pocket left by the machine stitch. However, the end result still looks better to me than a second hand machine stitch job.

Some of you might ask, was it worth the trouble :lol: ?

Cheers, Dave