Skyhawk

Well-Known Member

Hey guys, I thought I would post these tips on how to operate these antiquated zippers flawlessly without risking jamming or breaking teeth. In the past I have sent instructions with every Hookless jacket. It's a pretty simple method but there are pitfalls to look out for with these zips.

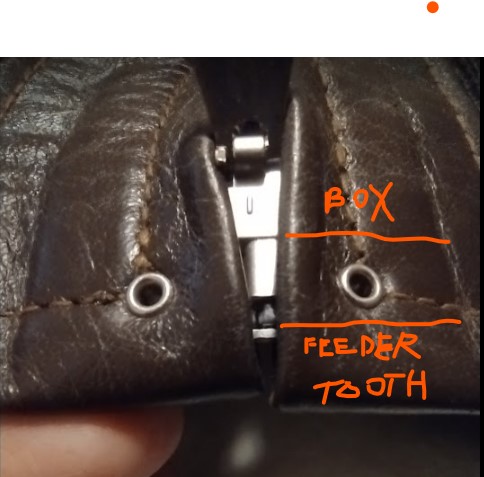

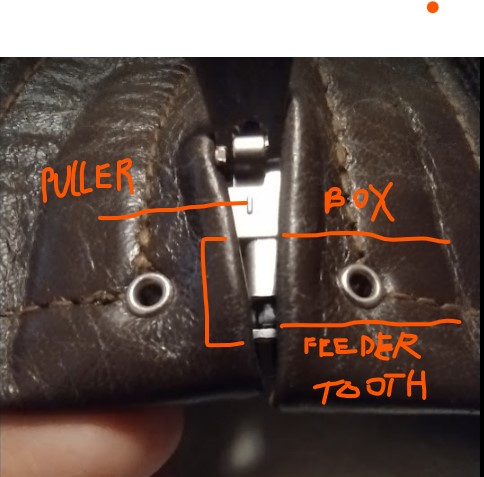

Generally, you have to wiggle the puller a little to find the right angle for it to seat against the box. Once you are sure that the puller is all the way down against the box, then you have to insert the feeder tooth all the way into the box, so that the tooth hits the bottom. Then hold down the left side as you zip, so the feeder tooth doesn't move up in the box while zipping. If you do these things, the zip will work flawlessly.

If you don't seat the zip all the way into the box, you can bend and break teeth, and jam the zipper. This is what happens in 99% of the cases of broken Hookless zippers. Also you need to remember to hold down the left side as you zip because the feeder tooth can slide up off the bottom if you don't.

Generally, you have to wiggle the puller a little to find the right angle for it to seat against the box. Once you are sure that the puller is all the way down against the box, then you have to insert the feeder tooth all the way into the box, so that the tooth hits the bottom. Then hold down the left side as you zip, so the feeder tooth doesn't move up in the box while zipping. If you do these things, the zip will work flawlessly.

If you don't seat the zip all the way into the box, you can bend and break teeth, and jam the zipper. This is what happens in 99% of the cases of broken Hookless zippers. Also you need to remember to hold down the left side as you zip because the feeder tooth can slide up off the bottom if you don't.

Last edited: